What Is the Difference Between Welded and Seamless Steel Pipes?

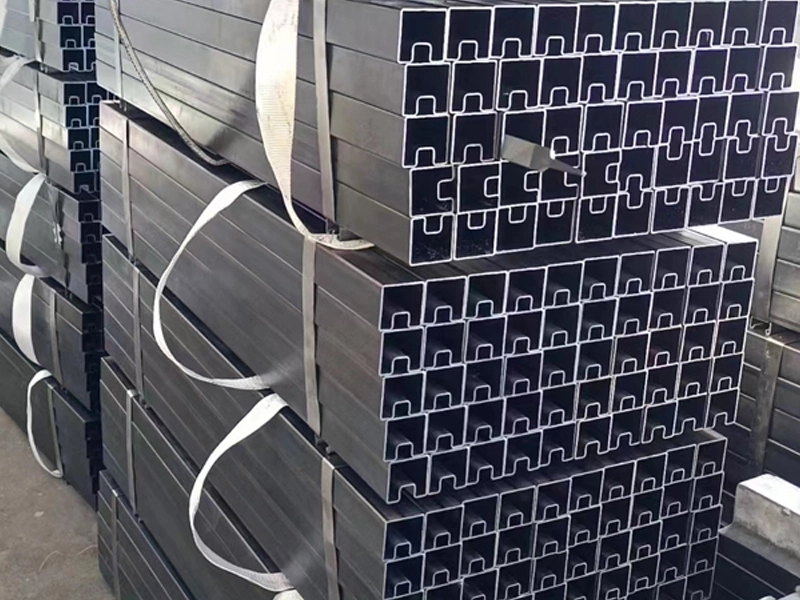

Welded and seamless steel pipes differ primarily in their manufacturing process, significantly impacting their structure, performance, and application—with quality options from trusted seamless steel pipe factory partners. Welded pipes are made by forming and welding steel sheets or plates around their circumference, creating a seam. This process allows for the production of large diameters and specific shapes at a lower cost. However, the presence of a seam can be a weak point, especially under high pressure. Seamless pipes, on the other hand, are manufactured by extruding steel at high temperatures, creating a pipe without seams—available as seamless steel pipe for sale across industrial sectors. This seamless construction provides superior strength and durability, making seamless ss pipe ideal for high-pressure applications and environments where pipe integrity is critical, supported by reliable seamless steel tube suppliers worldwide. Seamless pipes generally have a higher price point due to their complex production process but offer enhanced performance in demanding conditions, with customizable solutions from professional steel seamless pipe factory teams.

EN

EN