1、 Basic definition

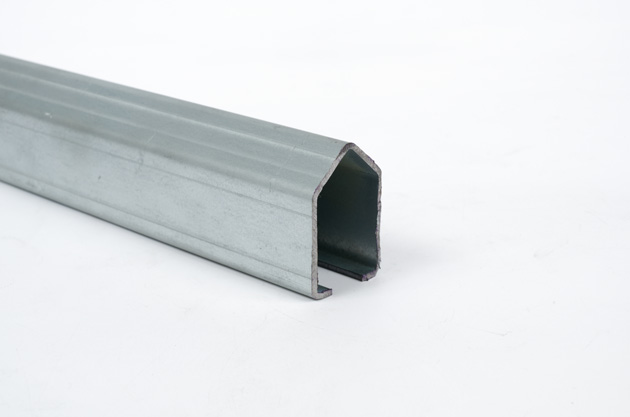

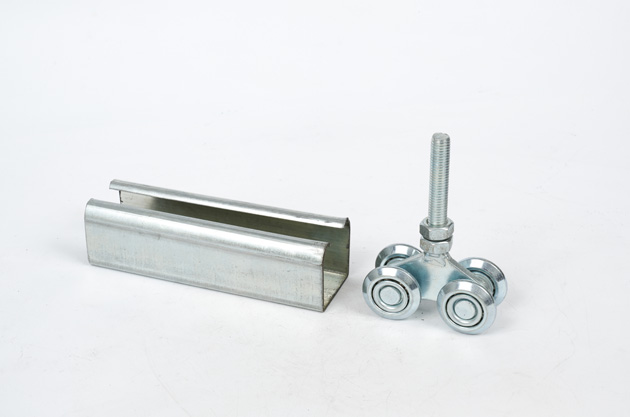

Cold formed channel steel is a type of cold-rolled steel that is bent into a beam shape through the cold rolling process. It is generally made of materials such as Q235B and Q345B, and has various specifications, such as C-shaped channel steel, Z-shaped channel steel, U-shaped channel steel, etc.

2、 Characteristics

1. The surface of cold-formed groove steel is flat and smooth, with high dimensional accuracy, good strength and toughness.

2. Cold formed channel steel is lightweight and has good processability, making it suitable for on-site construction and dismantling. It is a relatively economical and practical building material.

3. The processing method of cold-formed channel steel is mostly on-site processing, which can be cut, hole processed and other methods according to design standards, making it convenient and fast.

3、 Application field

1. Construction field: Cold formed channel steel is mainly used in various types of building structures such as beams, columns, and purlins in industrial factories, warehouses, sports venues, etc.

2. Mechanical manufacturing field: Cold formed channel steel can be used to produce various mechanical components, such as bridges, cranes, conveyors, stamping machines, etc.

3. Road traffic field: Cold formed channel steel can be widely used as road guardrails, road sign posts, etc. in road traffic facilities.

4. Other fields: Cold formed channel steel can also be used to make home and display equipment such as shelves, exhibition stands, decorative screens, etc.

In summary, cold-formed channel steel, as an important building material, has the characteristics of high precision, good strength, and strong machinability, and has been widely used in multiple fields.